Why Choose London Resin for Commercial Projects

If you’re managing a space in London – a school courtyard, a hotel entrance, a retail park walkway or a residential development – you need a surface that looks great, lasts, and can handle heavy footfall without constant upkeep. That’s exactly what our resin bound systems deliver.

We handle the full installation in-house: excavation, sub-base preparation, Structural Reinforcement Mesh, Vubamac base and the final resin bound finish. No outsourcing, no shortcuts.

And because we’re a Vuba Elite Installer, you get industry-recognised quality, backed by premium materials and proven installation standards.

Typical Commercial Applications

Education

Safe, accessible, low-maintenance surfaces for playgrounds, courtyards, multi-use areas and pathways. Ideal for schools, nurseries, academies and universities across London.

Hospitality & Leisure

Premium finishes for hotel forecourts, outdoor dining spaces, roof terraces, pool surrounds and entrance areas. A clean, modern first impression for guests.

Retail & Business Parks

Durable, professional surfacing for car parks, access routes, loading bays and busy pedestrian areas — designed to handle constant footfall and light traffic.

Healthcare

Joint-free, non-slip, compliant surfaces for hospitals, GP surgeries, private clinics and care homes. Perfect for drop-off zones, ambulance routes and staff car parks.

Local Authority & Public Realm

Attractive, functional, low-maintenance surfacing for community spaces, parks, walkways, estates and civic projects. Fully permeable and environmentally considerate.

Residential Developments

Show-home driveways, communal courtyards, mews streets and shared-access areas finished in a way that elevates the entire development.

UK Standards & Compliance

Our systems are installed in line with relevant UK standards and good practice:

BS 7533-13 – design and construction of permeable pavements

BS 7976 – slip resistance for pedestrian surfaces

SuDS Guidance (DEFRA) – sustainable drainage compliance

Building Regulations Part M – accessibility and inclusive design

CDM Regulations 2015 – full adherence to health and safety requirements

A Smarter Alternative to Traditional Surfacing

Resin bound surfacing has quickly become one of London’s most reliable and attractive choices for commercial environments. It outperforms tarmac, concrete and block paving by offering a smooth, seamless finish that’s fully permeable, slip-resistant and built to last.

Created by binding natural decorative aggregates with a high-performance polyurethane resin, it’s available in a huge range of colours – from contemporary greys to warm natural blends. In many cases it can even be laid over existing surfaces, helping reduce disruption on live sites.

It’s ideal for:

- Car parks

- Courtyards & public spaces

- Access roads & forecourts

- Playgrounds & pathways

- Communal residential areas

- Cycle, scooter & delivery bays

And because there are no joints, it looks cleaner, stays cleaner and doesn’t suffer from weed growth or cracked lines.

Why SuDS Compliance Matters in London

London is one of the most heavily built-up cities in the world – and with so much hard landscaping, surface water can become a real problem.

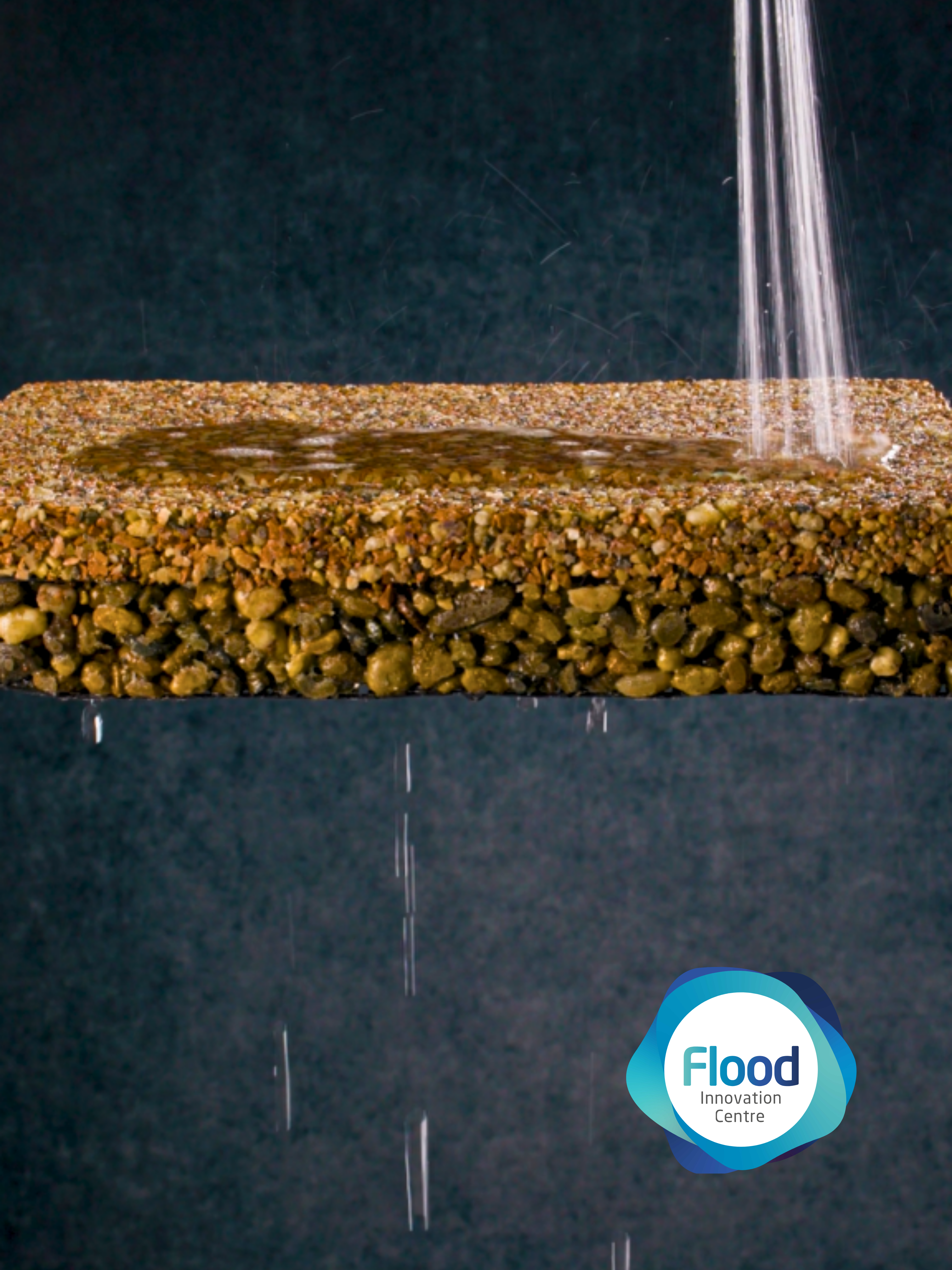

A SuDS-compliant resin bound system allows rainwater to drain through the surface into the open-graded sub-base, helping reduce runoff, puddling and localised flooding. It’s exactly the kind of sustainable, low-impact solution London planners and developers now look for.

Drainage

Because the surface is fully permeable, rainwater drains through instead of sitting on top or overwhelming traditional drainage points. This reduces the risk of puddles, standing water, blocked gullies and day-to-day maintenance headaches — especially in high-traffic areas like car parks, courtyards and entrance routes.

Safer surfaces in wet and winter conditions

With no pooling, ice patches are far less likely to form in winter. The textured, slip-resistant finish also provides reliable grip year-round, making it ideal for schools, healthcare sites and busy public spaces where safety can’t be compromised.

Reduced pressure on London’s ageing drainage network

London’s drainage infrastructure is under constant strain. A SuDS-compliant resin system helps divert water away from overloaded pipes and sewers by allowing natural infiltration into the sub-base and ground below. It’s a small change that has a meaningful impact in dense urban areas.

Potential planning advantages on new developments

Local authorities increasingly look for SuDS-friendly solutions as part of planning approvals. Using a permeable resin bound system - especially on larger developments, mixed-use schemes or refurbishments — can support planning applications, demonstrate sustainability, and align with modern drainage policy.

Performance & Benefits

- Permeability: Full-depth system supports infiltration and SuDS compliance

- Load-bearing structure: Type 3 MOT + SRM + Vubamac base engineered for stability

- Slip resistance: Designed to meet required PTV values for public routes

- UV resistance: Aliphatic resin ensures long-term colour performance

- Maintenance: Low lifecycle cost; requires only sweeping and occasional washing

- Finish quality: Hand-trowelled surface provides uniform 18–24mm wear layer

- Aggregate range: Multiple blend options suitable for commercial palettes

- Environmental performance: Reduces runoff and pressure on drainage systems

- Installation speed: Rapid curing minimises downtime on live sites

- Lifespan: Expected service life of 20+ years with correct maintenance

Our Commercial Installation Build-Up

Excavation & Site Preparation

Carried out to the required depth, removing all existing material, soft spots and vegetation. Levels and falls are set to ensure correct drainage and surface uniformity.

Type 3 MOT Sub-base

An open-graded, permeable sub-base installed, compacted and levelled. This forms the primary load-bearing layer and is essential for SuDS performance. Its high void content allows water to drain freely through the system.

Capping Layer (Stabilisation Layer)

Installed above the Type 3 where additional stabilisation or levelling is required. This layer helps strengthen the base, supports even load distribution and creates a more uniform platform before reinforcement.

SRM (Structural Reinforcement Mesh)

Reinforcement mesh placed over the sub-base structure to increase strength, reduce movement and improve performance under commercial footfall and light vehicular use.

Vubamac Base System

A permeable, resin-bound base layer engineered specifically for resin installations. It provides exceptional stability, reduces movement and enhances long-term structural integrity.

Resin Bound Surface

SRM is installed, followed by a 15–24mm UV-stable aliphatic resin bound layer using high-quality natural aggregates. The surface is hand-trowelled to create a premium, seamless, slip-resistant and fully permeable finish.

Recent Projects

A quick look at some of the commercial spaces we’ve upgraded across London. Each project is a bit different – schools, memorials, sports clubs, forecourts – but the goal is always the same: create a durable, clean-looking, fully permeable surface that performs day in, day out. Here are a few highlights.

Globe Lawn Tennis Club, London – Project Summary

London Resin transformed the terrace and access pathways at Globe Lawn Tennis Club in NW3, creating a more durable, attractive and low-maintenance surface for players and spectators. We removed old flower beds, installed a fresh permeable sub-base and overlaid the existing concrete with a high-performance resin bound system.

A total of 267m² was resurfaced using a combination of Idaho and Tallahasse blends – the latter chosen to complement the clay courts and create a visually seamless environment. The result is a smooth, slip-resistant area that enhances safety, usability and overall presentation for both members and visitors.

Gunnersbury Park Humanitarian Memorial – Project Summary

London Resin was appointed to install a high-quality resin bound surface at the Humanitarian Memorial in Gunnersbury Park, supporting the site’s sensitivity and design vision. Our team prepared the area, installed a permeable base structure and hand-laid a resin bound finish that provides both longevity and a refined visual appearance.

The new surface ensures accessibility, durability and year-round usability while respecting the memorial’s architectural design. Fully permeable and low-maintenance, it offers a modern, understated finish that complements the surrounding landscape.

FAQs

Typically:

Excavation to depth

Type 3 MOT sub-base

Structural Reinforcement Mesh

Vubamac bound base layer

SRM levelling layer

Resin bound surface (18–24mm)

The exact depth varies depending on usage and base requirements.

Yes – for light vehicle traffic such as car parks, staff parking, delivery bays and access roads. For heavy goods or constant turning HGV traffic, further base reinforcement will be needed and resin may not be the optimal surface.

It is SuDS compliant when installed over a permeable sub-base, such as Type 3 MOT with a Vubamac bound layer. If installed over impermeable asphalt or concrete, it becomes a non-SuDS system unless drainage is introduced.

Extremely well – because:

It has no joints to allow water penetration

The entire system is permeable, reducing trapped moisture

It’s UV-stable and resistant to cracking

This makes it particularly suitable for external public spaces.

Resin bound typically achieves PTV > 36 in wet conditions, meeting UK slip-resistance standards for public areas. Aggregate size affects slip resistance and can be chosen based on project needs.

Yes, provided the existing surface is stable, crack-free and has correct falls. We can repair and adjust it if needed. If the existing base is unsuitable, we install a new Type 3 MOT and Vubamac system.

Yes – recessed trays are resin-filled to match the main surface, delivering a seamless finish. We integrate:

ACO channels

Slot drains

Gully points

Threshold drains

- Foot traffic: 24 hours

- Vehicles: 72 hours

Temperature and humidity can influence curing slightly.

Yes – it’s smooth, seamless and provides excellent grip. Ideal for:

- DDA-compliant routes

- Wheelchair access

- Pushchair-friendly surfaces

- Gentle gradients

Yes – using contrasting aggregate blends and templates. Perfect for branding, wayfinding or design-led schemes.

With correct installation and maintenance:

20+ years for commercial use.

Resin bound generally has:

Lower long-term maintenance cost

Better permeability

Longer visual lifespan

No joint failures or weed growth

It often provides a superior whole-life cost for commercial settings.

No more than traditional paving. Choosing lighter colours can reduce heat absorption further.

Occasional sweeping

Light power washing

Immediate removal of oil spills

Annual inspection recommended for commercial sites

Maintenance is minimal compared to other surfaces.

Our Clients

Working With You

We regularly collaborate with:

Main contractors and developers

Architects and designers

Facilities and estates managers

Local councils and education trusts

Whether you’re managing a school upgrade, a hotel refurbishment or a retail park improvement, our team provides practical advice, clear pricing and reliable delivery.

Request a FREE Quote

We’re confident we can beat “like-for-like” quotes and complete your project to a better standard than our competitors.

Why Choose Us?

At London Resin, we pride ourselves on our long-standing reputation for excellence in resin surfacing. With decades of experience, our team is dedicated to delivering high-quality results tailored to your needs.

30+ Years' Experience

Leveraging our three decades of expertise for reliable and skilled resin surfacing solutions.

10-Year Guarantee

You can rest easy knowing that your new surface is covered with our 10-year guarantee.

Exceptional Workmanship

Every project is handled by our team with the utmost care, dedication and attention to detail.

First-Class Service

You can depend on our team to deliver excellent customer service at all times.